Our Process

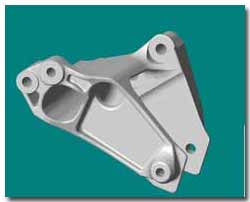

CAD and Solid Modeling

Reliable utilizes a number of CAD Tools to provide casting design assistance. Part and mold designs are optimized for manufacturing efficiency.

Product Design Improvement Process

Foundry tooling is produced in our pattern and fully-equipped machine shop using a variety of CAD/CAM software including KeyCreator, SurfCAM, Work NC, and AutoCAD supporting latest technology CNC machine centers.

Flow and Solidification Modeling

Reliable Castings utilizes several simulation modeling tools to engineer and assure quality through casting and process design.

FLOWCast Modeling

FLOWCast modeling allows a pouring simulation which will lead to understanding the best way to conduct the cast and see where any quality concerns may arise during the process, and to determine the optimal cast process.

Solidification Modeling

To analyze flow and processing characteristics for optimum tool design, we use Finite Solution’s SOLIDCast solidification modeling. We use OPTICast and FLOWCast modeling software to analyze gating/risering yield efficiencies and metal in-flow turbulence reduction design.

Methods Development

Product Design Improvement Projects (Kaizen) Past Examples

Reduction of raw casting weight by 5% on brake calipers, also reducing our customers machining time by 1.3 minutes per part.

Reduction of machine stock on ABS bodies resulting in a 9% weight reduction and also reducing our customers machining time.

Elimination of “cored” hole on ABS bodies, improving product quality and ease of machining for our customer.

Process Design Engineering

Advanced Product Quality Planning

Process flow diagrams

- kanban requirements identified

Process failure mode and effects analysis

- pokayoke opportunities identified

- kaizen opportunities identified

Process control plans

- testing requirements

- measurement systems

- auditing plans

Process work instructions

- safety requirements & plans

- education & training plan

Reliable Improves castability to increase production efficiency and lower costs…

Reliable makes sure that castings are engineered to meet customer quality standards and to ensure that designs are optimized for manufacturing ease.

By optimizing the part’s design before any molds are cut, you benefit from:

Reducing sampling costs because fewer test runs are needed

Starting production with fewer defects

Improving overall yield

Maximizing the number of impressions per mold

Increased profits by reducing development time, getting into production sooner, and speeding time to market

To ensure that castings meet all application requirements, Reliable produces prototype parts for comprehensive testing under actual assembly and production conditions. Throughout the prototype phase, our engineers analyze test results and fine-tune designs to achieve optimum production efficiency.